Blog

Aluminum Wire Coating Tips for Better Durability and Performance?

In the Aluminum Wire Coating industry, experts emphasize the importance of durable coatings. John Anderson, a leading specialist, stated, “A well-coated aluminum wire can outperform expectations.” This highlights the critical role of Aluminum Wire Coating in enhancing performance and longevity.

Choosing the right coating material is essential. Coatings protect aluminum wires from environmental factors. They reduce oxidation and degradation. However, not all coatings provide the same level of protection. Some may wear down too quickly. This can lead to failures and increased costs.

Attention to detail matters. A thick application can hinder flexibility, while a thin one might not offer sufficient protection. Evaluating the coating process is vital for optimal results. Regular quality checks can prevent potential issues. Balancing durability with performance requires expertise and careful consideration. The path toward achieving the best Aluminum Wire Coating involves constant reflection and adjustment.

Aluminum Wire Coating Methods: An Overview

Coating aluminum wire is essential for enhancing durability and performance. Various methods exist, and each has unique benefits. The electrostatic spray coating method is popular in the industry. According to a recent report, over 40% of manufacturers prefer this method. It provides a uniform layer and excellent adhesion. However, achieving consistent thickness can be challenging.

Another method is dip coating, a simpler and more cost-effective approach. Studies show that this method can reduce production time by up to 30%. It’s effective for thicker coatings, but it often lacks the finesse of spray methods. Surface preparation is critical; even minute residues can impact the final outcome. Despite advancements, many companies still overlook this step.

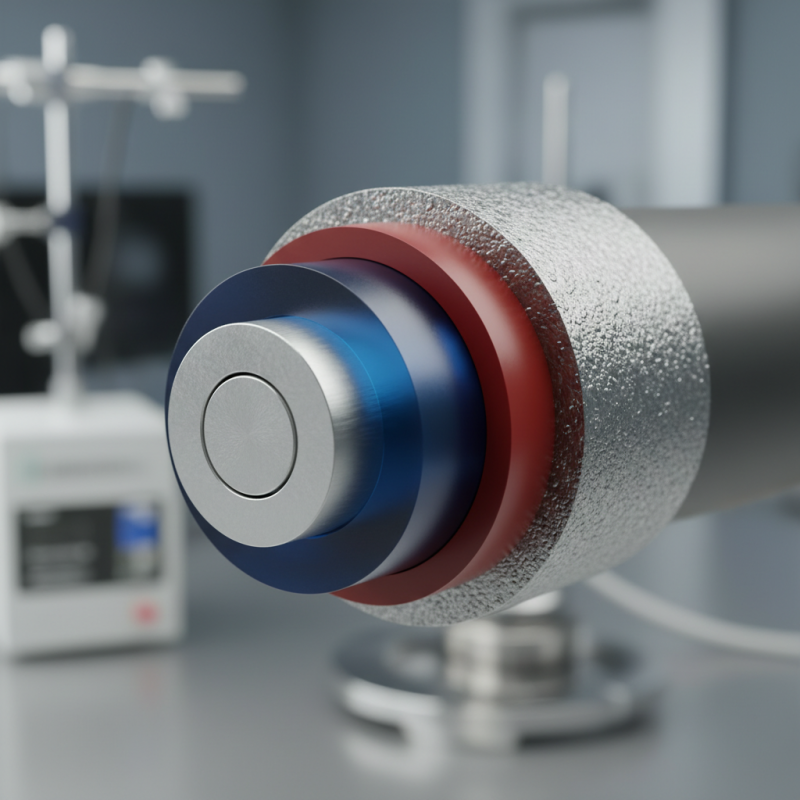

Thermal spray methods are also notable. These methods offer high resistance to heat and corrosion. However, they can be resource-intensive and require skilled operators. As reported, the industry faces a skills gap. Many technicians are not fully trained in advanced techniques. There’s a need for improved training to utilize these methods effectively. Balancing cost, efficiency, and quality remains an ongoing challenge. Each coating method has its place, but careful consideration is vital.

Aluminum Wire Coating Tips for Better Durability and Performance

| Coating Method | Durability Rating (1-10) | Performance Benefits | Typical Applications |

|---|---|---|---|

| Polyurethane Coating | 9 | Excellent abrasion resistance, flexible | Electrical insulation, automotive |

| PVC Coating | 7 | Good chemical resistance, cost-effective | Construction, wiring |

| Epoxy Coating | 8 | Strong adhesion, weather-resistant | Marine applications, outdoor use |

| Enamel Coating | 6 | Good aesthetics, moderate protection | Appliances, decorative items |

| Thermal Spray Coating | 10 | Superior hardness, wear resistance | Industrial machinery, tools |

Factors Influencing Coating Durability in Aluminum Wires

When selecting coatings for aluminum wires, several factors come into play. The type of coating used significantly affects durability. Polyurethane, epoxy, or PVC coatings offer varying levels of protection against environmental stressors. For instance, UV exposure can degrade some coatings more quickly than others. In environments with high humidity, moisture-resistant coatings become essential to prevent corrosion.

Surface preparation is another critical aspect. A clean and properly treated wire surface enhances adhesion, helping the coating to bond effectively. Failure to prepare the surface can result in peeling or chipping, compromising the wire’s longevity. Additionally, application methods like spraying or dipping must match the coating type. Improper application can lead to thin spots or uneven coverage.

Environmental conditions during application also matter. Extreme temperatures can affect curing times and final coating integrity. This inconsistency may require reevaluation of the coating process. Identifying these factors is essential for achieving optimal performance and durability in aluminum wire applications. Each step should be viewed as an opportunity for improvement rather than a mere checklist.

Performance Enhancements through Advanced Coating Techniques

When it comes to aluminum wire, advanced coating techniques play a pivotal role in enhancing durability and performance. A well-executed coating can protect against harsh environmental factors. This results in improved electrical conductivity and extended lifespan of the wire. However, achieving the perfect balance in coating thickness and material is often a challenge. Overly thick coatings may impede performance, while too thin layers can leave the wire vulnerable.

One key tip is to choose the right coating material. A high-quality polymer can resist corrosion effectively. It will also help reduce wear under stress. Additionally, applying the coating in controlled environments can prevent contamination. Dust and humidity can interfere with adhesion. Proper surface preparation is essential. A clean, roughened surface ensures better bonding of the coating.

Another important factor is the curing process. Insufficient curing can lead to poor durability. Be mindful of the temperature and time required for optimal results. Monitoring the curing conditions can make all the difference. All these elements require careful consideration. Sometimes, even minor adjustments can lead to significant performance improvements. It’s essential to test and analyze the results continuously.

Aluminum Wire Coating Durability and Performance Enhancements

Maintenance Best Practices for Coated Aluminum Wires

Coated aluminum wires offer excellent durability and performance. However, proper maintenance is crucial for their longevity. Regular inspections can identify any signs of wear or damage. Look for peeling or discoloration, as these can indicate deterioration in the coating. Keeping the wires clean is essential; dirt and grime can compromise their protective layer.

Incorporating a routine cleaning schedule can help maintain the integrity of the coating. Use mild soaps and soft brushes to avoid scratching. Over time, you may notice areas where the coating appears thin or worn. These spots may need attention sooner than you expect. When in doubt, it’s best to reapply the coating or consult a professional for advice.

Another aspect to consider is environmental exposure. High humidity, extreme temperatures, and UV radiation can negatively impact coated wires. Storing them in a sheltered area can mitigate some of these effects. Remember, neglecting these details might lead to premature failure, which can affect overall performance. Pay attention, and your coated aluminum wires will last longer.

Common Challenges and Solutions in Aluminum Wire Coating

Aluminum wire coating presents several challenges that can affect durability and performance. One common issue is adhesion. If the coating doesn't bond well, it can peel off. This often happens due to surface contamination. Oils, dust, or moisture can lead to poor results. Cleaning the wire surface thoroughly is crucial. A simple wipe down with a solvent can help eliminate these contaminants.

Another challenge is the coating thickness. Too thick a layer may not cure properly. This can result in bubbles or cracks. Conversely, a layer that's too thin may not provide adequate protection. It's essential to find a balance. Using a precise application tool can help manage thickness effectively.

Temperature control during curing also impacts results. If the temperature fluctuates, the coating might not set correctly. This leads to uneven surfaces. Monitoring the environment where coating takes place is important. Inconsistent conditions can ruin the entire batch. Keeping a steady temperature helps maintain quality. It's these small details that often make a big difference.