Blog

What is a Digital Flatbed Printer and How Does it Work?

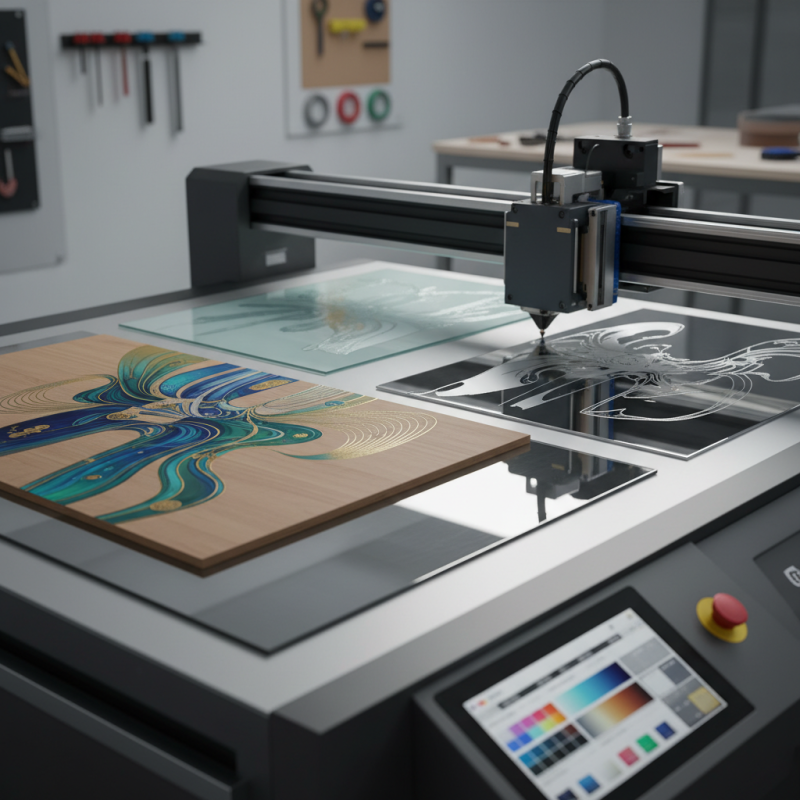

A Digital Flatbed Printer is an innovative tool in the printing industry. It allows for high-quality printing on various surfaces, such as wood, glass, and metal. Unlike traditional printers, it uses a flat surface to feed materials directly into the machine. This process opens new possibilities for creative designs and applications.

With its versatility, a Digital Flatbed Printer can meet different market needs. It is increasingly popular among businesses that require custom solutions. However, operating such a printer requires a solid understanding of its technology. Users must learn about color management and material compatibility. These aspects can be challenging.

Using this printer can lead to impressive results. Yet, it is essential to be aware of potential issues. Print quality can vary based on the material used. There can also be limitations in color accuracy. Learning from these experiences can enhance the overall output. Embracing both the benefits and the challenges leads to better printing solutions.

What is a Digital Flatbed Printer?

A digital flatbed printer is a powerful tool in printing technology. It allows for printing on a variety of materials, such as wood, metal, glass, and plastic. Unlike standard inkjet printers that use sheets of paper, flatbed printers utilize a flat surface, making them versatile and efficient.

These printers work by directly applying ink onto the material's surface. They use UV printing technology, which cures the ink as it is printed. This process results in vibrant colors and sharp details, essential for high-quality outputs. The printer's ability to handle thick and rigid substrates sets it apart from other printing methods.

Tips: When choosing a flatbed printer, consider the types of materials you will use. Compatibility is crucial for achieving the best results. Additionally, ensure that you maintain the printer regularly. Dust and ink buildup can affect print quality.

Another essential aspect is the software used. A user-friendly interface can save time and frustration. Many users overlook the importance of thoughtful layout design. A poorly planned design can lead to wasted materials and unhappy clients. Always focus on precision and planning in your printing projects.

Key Components of Digital Flatbed Printers

Digital flatbed printers are powerful tools for various printing needs. They operate using several key components that ensure high-quality printing on different materials. One important part is the print head. This component sprays ink directly onto the substrate, allowing for detailed prints. Inkjet technology is often employed here, enabling vibrant colors and fine details.

Another crucial component is the flatbed surface. It provides a stable base for materials, ensuring precision during the printing process. The bed can accommodate various substrates, such as wood, glass, and metal. However, aligning materials properly can be challenging. Any misalignment may lead to poor-quality prints.

Additionally, the control system regulates the printer's operations. It controls the speed and amount of ink used. A well-tuned system is essential for efficiency. Yet, maintaining this system can be tricky. Regular adjustments may be needed to keep everything running smoothly. The interplay among these components is vital for achieving the best results in digital flatbed printing.

How Digital Flatbed Printers Operate

Digital flatbed printers are remarkable tools in the printing industry. They operate using a unique method of direct printing. This allows printing on various materials, including wood, metal, and glass. The printer uses UV (ultraviolet) light to cure inks as they are laid down, resulting in high-quality, durable images.

In operation, flatbed printers employ a stationary bed where substrates rest during printing. Print heads move across the bed, depositing ink in precise patterns. The process is automatic, which reduces manual labor. Each layer of ink dries quickly due to the UV curing process, enabling efficient production. However, this technology can have some limitations. For instance, achieving perfect color accuracy can be challenging. Customers may find discrepancies in color between prints.

Moreover, while flatbed printers handle thick materials well, not all designs translate seamlessly onto flexible substrates. Choosing the right settings is crucial to avoid misprints or smudging. These nuances can sometimes lead to reflections on the overall quality of the final product. Each project reveals something new about this technology. It encourages users to adapt and refine their approaches continually.

Applications and Uses of Digital Flatbed Printing

Digital flatbed printing has gained popularity across various industries due to its versatility. It allows printing on a wide range of materials such as wood, glass, metal, and fabrics. Businesses use this technology to create custom signage, promotional displays, and packaging. The ability to print directly on these substrates makes it ideal for unique projects.

In the realm of signage, digital flatbed printers excel. They produce vibrant graphics and intricate designs that catch the eye. Many companies create decorative wall art or branded items with this technology. However, things don't always go perfectly. Sometimes color mismatches occur or materials warp. It requires keen attention to detail and adjustments along the way.

In retail, digital flatbed printing plays a vital role in product packaging. Companies can achieve high-quality visuals and innovative designs that stand out on store shelves. Yet, the learning curve can be steep. Not every project meets expectations. Feedback is crucial for improving future prints. Each project presents an opportunity to refine skills and increase creativity.

Benefits of Using Digital Flatbed Printers

Digital flatbed printers are revolutionizing how we produce high-quality prints. Their versatility is unmatched. These printers can print on various materials, including wood, glass, and metal. This feature opens new avenues for creative endeavors. For businesses, this means the ability to customize products easily. However, precision is key. If not calibrated correctly, the output can vary greatly.

One of the notable benefits is the speed of production. Digital flatbed printers can produce complex designs quickly. This rapid output helps businesses meet tight deadlines. Yet, quality control can be a challenge. Sometimes, the color accuracy isn’t as expected. It requires a keen eye to catch these nuances.

Moreover, these printers reduce waste. Unlike traditional methods, they use ink more efficiently. This aspect not only saves costs but is also better for the environment. Although, there are still improvements to be made in ink longevity. Some prints may fade faster than desired. It's a growing concern for many creators looking for durability.

Benefits of Digital Flatbed Printers

This chart illustrates the key benefits of digital flatbed printers, displaying how they excel in speed, quality, cost-effectiveness, versatility, and durability. Each benefit is rated out of 100, showcasing their significance in the printing industry.