Blog

What is a High Speed Inspection Machine and How Does It Work?

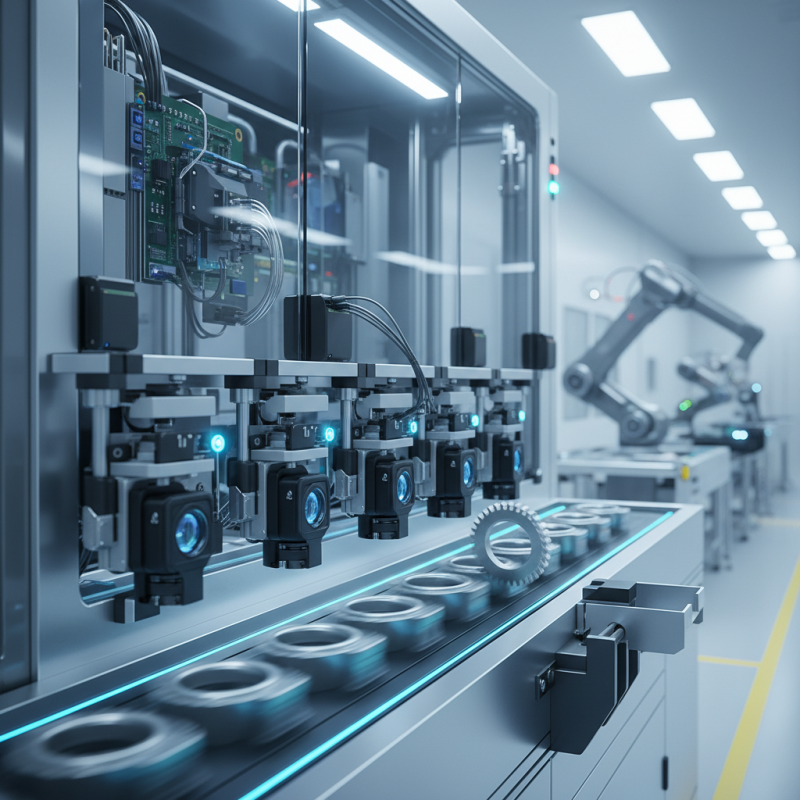

In today's fast-paced manufacturing world, efficiency is crucial. A High Speed Inspection Machine plays a vital role in this context. It ensures quality control while maintaining high throughput. These machines inspect products at incredible speeds, checking for defects and inconsistencies. They utilize advanced technology, such as cameras and sensors, to perform real-time analysis.

However, the implementation of a High Speed Inspection Machine comes with challenges. Companies must balance speed and accuracy. A machine that operates too fast might miss critical defects. It's essential to calibrate these machines properly. Regular maintenance and updates are necessary to prevent malfunctions.

Understanding how a High Speed Inspection Machine works can benefit manufacturers significantly. Learning about its mechanisms encourages reflection on process improvements. In a competitive landscape, embracing such technology can lead to superior product quality and customer satisfaction. Yet, organizations must continually evaluate its effectiveness and adaptability to evolving standards.

What is a High Speed Inspection Machine?

A high-speed inspection machine is designed to ensure quality and accuracy in manufacturing. It scans products quickly. This machine uses various technologies like cameras and sensors. They detect defects and irregularities with high precision. Many industries rely on these machines to maintain standards.

These machines operate on the principle of automation. They can process products at incredible speeds, often exceeding a thousand items per minute. The real challenge lies in the software that interprets data efficiently. Sometimes, the algorithms struggle with complex defects. This can lead to false positives or missed errors, which requires continuous refinement.

Reflection on the design of high-speed inspection machines is essential. While they can enhance productivity, the technology must evolve with changing products. Each industry has unique challenges that standard machinery may not fully address. So, ongoing innovation and adaptation are crucial to meet diverse quality demands.

Key Features of High Speed Inspection Machines

High-speed inspection machines play a crucial role in various industries. Their main function is to analyze products quickly and accurately. This ensures that only quality items reach consumers. Recent studies show that these machines can increase inspection speeds by up to 300% compared to manual processes. This efficiency is vital in cost reduction and maintaining product standards.

One of the key features of high-speed inspection machines is their advanced imaging technology. They use high-resolution cameras to capture detailed images of products. Some systems incorporate artificial intelligence for real-time analysis. This helps identify defects that might go unnoticed by human inspectors. Reports indicate that using such technology can reduce inspection errors by more than 15%.

Another important aspect is their adaptability. High-speed inspection machines can be tailored for different products and production lines. This flexibility is essential for manufacturers facing diverse demands. However, training staff to operate these advanced systems remains a challenge. Investments in proper training are necessary, as poor handling can lead to operational inefficiencies, undermining the benefits of these machines.

Principles of Operation for High Speed Inspection Machines

High-speed inspection machines play a crucial role in modern manufacturing. They are designed to enhance the quality control process efficiently. These machines use various technologies, including cameras and sensors, to detect defects in products rapidly. Typically, they can inspect items at speeds exceeding 600 units per minute. This capability minimizes downtime and increases operational productivity, making a significant impact on the overall efficiency of production lines.

The principles of operation for these machines revolve around image processing and data analysis. High-resolution cameras capture images of products as they move along the production line. Software algorithms then analyze these images to identify imperfections. Research shows that automated inspection can reduce labor costs by up to 50%. However, accuracy can sometimes be a challenge. False positives can lead to unnecessary rework, while false negatives might allow defects to pass through unnoticed.

Tip: Regular calibration of inspection machines is vital for maintaining accuracy. Small misalignments can skew results, causing potential issues. Operators should also be trained thoroughly. Machine settings can vary, depending on the product and production speed. Therefore, adapting the approach as needed is essential. Continuous monitoring will help ensure that inspection quality remains high.

High Speed Inspection Machine Performance Metrics

Applications in Various Industries

High-speed inspection machines play a crucial role in various industries, ensuring product quality and safety. In manufacturing, they can achieve speeds of up to 1,200 parts per minute. These machines utilize advanced imaging technology to detect defects in real-time. For instance, a report by Smithers Pira indicates that the global inspection systems market is projected to reach $2.6 billion by 2025. This growth highlights the increasing reliance on automated inspection processes.

In the food industry, high-speed inspection machines are vital for ensuring compliance with health regulations. They check packaging integrity and the presence of foreign materials. A study found that 95% of food manufacturers use some form of inspection technology. However, many still face challenges, such as false positives and equipment malfunctions. This raises concerns about maintaining consistent quality without compromising productivity.

Pharmaceuticals also benefit from high-speed inspections, particularly in verifying label accuracy and package integrity. The market demand is growing, with an expected increase of 8% annually. Despite advancements, some manufacturers struggle to adopt these technologies fully. Integration can be complex, leading to errors. These challenges must be addressed for industries to maximize the potential of high-speed inspection machines.

Advantages and Limitations of High Speed Inspection Machines

High speed inspection machines are transforming quality control across various industries. These machines can inspect thousands of products per minute. According to industry reports, they can achieve 97% accuracy in detecting defects. This efficiency helps manufacturers reduce waste and improve product quality.

However, these machines have their limitations. They require precise calibration and skilled operators. If misconfigured, they can overlook defects. A report from a leading inspection technology organization highlighted that 15% of operators reported challenges in maintaining machine accuracy over time.

Moreover, costs can be significant. Investing in such technology may not be feasible for smaller manufacturers. Some companies might face budget constraints, leading to compromised quality checks. As technology evolves, industry players must weigh the benefits against potential risks.