Blog

Understanding the Limitations of Tower Lights in Industrial Applications

In industrial environments, effective communication and visibility are paramount, leading many organizations to implement Tower Lights as a solution for signaling and alerts. These multi-colored visual indicators serve crucial roles in enhancing operational awareness and safety by providing immediate notifications about the status of machinery or processes. However, despite their widespread use, it is essential to understand the limitations of Tower Lights in various industrial applications. Factors such as their visibility range, susceptibility to environmental conditions, and the limitations in conveying complex information can restrict their effectiveness. This blog will explore these challenges through real-world examples, emphasizing the necessity for industries to carefully assess their specific requirements and consider complementary systems to optimize communication and ensure safety.

Significance of Tower Lights in Industrial Settings

The significance of tower lights in industrial settings cannot be overstated. These essential devices serve as visual alerts and safety mechanisms that enhance operational efficiency in various industrial environments. Tower lights provide critical information through color-coded signals, indicating the status of equipment and processes. For instance, green typically signifies normal operation, while red can indicate a fault or issue that requires immediate attention. Their role is particularly vital in high-paced environments such as manufacturing and warehousing, where clear communication is key to preventing accidents and ensuring smooth workflows.

**Tips:** When implementing tower lights in industrial applications, consider the brightness and visibility requirements based on the working environment. Ensure that they are positioned at optimal heights and angles to maximize visibility from various vantage points. Additionally, choose tower lights with multi-function capabilities, as they can offer a broader range of notifications and save on the need for multiple signaling devices.

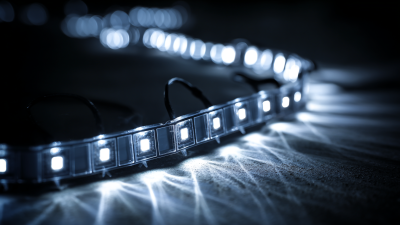

In terms of environmental impact, as industries move towards greener practices, integrating energy-efficient tower lights can significantly reduce carbon footprints. The evolution towards modern energy-efficient lighting options, such as LEDs, not only enhances visibility but also contributes to the overall energy savings within industrial operations. According to recent studies, energy efficiency is regarded as a fundamental element in achieving cleaner energy transitions, providing quick and cost-effective reductions in CO2 emissions.

Understanding the Limitations of Tower Lights in Industrial Applications

| Application Area | Significance | Common Limitations | Recommended Improvements |

|---|---|---|---|

| Manufacturing Floors | Alerts operators to status changes | Limited visibility in bright environments | Use higher intensity lights |

| Logistics & Warehousing | Indicates loading/unloading status | Potential confusion with multiple signals | Implement color coding |

| Construction Sites | Enhances visibility of hazards | Weather impacts performance | Use weatherproof designs |

| Process Industries | Monitors equipment status | Noise interference can mask alerts | Integrate auditory signals |

Common Challenges Faced in Using Tower Lights

Tower lights are essential signaling devices in industrial settings, but their use comes with several challenges. A primary issue is visibility. While tower lights are designed to stand tall and be seen from a distance, factors such as ambient light, dust, and obstacles in the environment can significantly reduce their effectiveness. This can lead to operators not receiving crucial visual alerts, which may result in accidents or miscommunication regarding equipment status.

Another common challenge is the complexity of integration with existing systems. Many industrial facilities employ various types of machinery and control systems, making it difficult to find a universally compatible tower light. Additionally, the electrical requirements and control interfaces can vary greatly, complicating installation and maintenance. If not properly integrated, tower lights may fail to provide real-time feedback, hindering their intended purpose in improving operational safety and efficiency. Addressing these challenges involves careful consideration of placement, compatibility, and environmental factors to enhance the reliability of tower lights in industrial applications.

Understanding the Limitations of Tower Lights in Industrial Applications

This bar chart illustrates the common challenges faced in using tower lights in industrial applications. The data represents the percentage of incidents attributed to each challenge.

Factors Influencing Tower Light Performance

In industrial applications, Tower Lights serve as crucial visual indicators, yet their performance can be significantly influenced by a variety of factors. One primary aspect to consider is the ambient lighting conditions. In brightly lit environments, the visibility of Tower Lights may become compromised, rendering them less effective as warning signals. It is advisable to select Tower Lights with high luminosity and adjustable brightness settings to ensure they remain visible regardless of the surrounding light levels.

Lastly, the environmental conditions can also play a significant role. Factors like dust, moisture, and temperature fluctuations can impact the longevity and performance of Tower Lights. To mitigate these effects, consider investing in lights that are specifically designed for industrial use, featuring protective casings and robust materials suited for harsh environments. Regular maintenance checks are also essential to ensure these systems are functioning at their best.

Innovative Solutions to Enhance Tower Light Effectiveness

In industrial settings, tower lights serve as essential signaling devices, yet their effectiveness can be limited by various factors such as environmental conditions and visibility range. To enhance the operational efficiency of tower lights, innovative solutions are emerging that address these challenges. According to a recent report by MarketsandMarkets, the global industrial automation market, which encompasses advanced signaling solutions, is expected to grow from $197 billion in 2020 to $296 billion by 2025. This growth signals a rising demand for technologies that ensure clear visual communication in busy industrial environments.

One of the most promising advancements is the integration of LED technology into tower lights. LED tower lights not only provide brighter illumination but also have a longer lifespan, reducing maintenance costs significantly. A study by the Illuminating Engineering Society reveals that LED lights can be up to 80% more energy-efficient compared to traditional incandescent bulbs. Additionally, the incorporation of smart technology, such as IoT connectivity, allows for real-time monitoring and management of signaling devices, providing detailed analytics on performance and maintenance needs. By adopting these innovative approaches, industries can maximize the effectiveness of tower lights, ensuring reliable operations and enhanced safety protocols on the shop floor.

Best Practices for Selecting and Maintaining Tower Lights

When selecting tower lights for industrial applications, it is essential to consider factors such as visibility, durability, and compatibility with the work environment. A study by the Industrial Safety and Health Administration (ISHA) highlights that over 30% of workplace incidents can be attributed to inadequate signaling and visibility. This underscores the importance of choosing tower lights that are bright enough to be seen from a distance, especially in large industrial settings.

LED tower lights, which offer high luminous efficacy and longer lifespan compared to traditional incandescent bulbs, are increasingly favored. They not only provide better visibility—up to 80% more than traditional lights—but also consume less energy, making them a cost-effective solution.

Maintaining tower lights is another critical aspect that directly affects operational efficiency. According to a report by the Maintenance and Reliability Center, regular inspections can increase the lifespan of industrial lighting systems by as much as 50%. This involves checking for lens cleanliness, ensuring proper bulb function, and monitoring for any structural damage. Incorporating a scheduled maintenance routine paired with real-time monitoring can greatly reduce downtime and prevent potential safety hazards.

Furthermore, using smart technology for tower light connectivity allows for immediate alerts on maintenance needs, ensuring that workers remain safe and operations run smoothly.

Related Posts

-

Understanding Industry Production Standards and Why Best Tower Lights Are Essential for Global Buyers

-

15 Best Led Light Tower Features You Need for Maximum Efficiency

-

Unlocking the Advantages of Best Commercial Solar Street Lights for Diverse Applications

-

5 Best Solar LED Lights to Illuminate Your Outdoor Spaces Perfectly!

-

Navigating Import Export Certifications for Best Solar Powered Street Lights for Global Buyers

-

The Future of Sustainable Illumination: Embracing Solar Powered LED Lights